Applications:

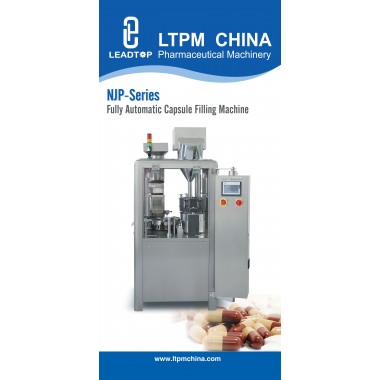

NJP-400C adopt PLC control system, human-machine interface, when running malfunction or lack of stuff, automatic alarm, malfunction display, automatic dismiss alarm. And with functions of password setup, touching screen display, automatic parameter setup, data printing, reset, etc.

The jump-start axed, cam and other main damageable parts all adopt imported materials. And the machine is suitable for Powder, Granular and Pellet filling, one hour for 24,000capsules, special for Capsule size from00# to 5#.

Main Technical Data:

Model: | 400C |

Capacity: | 400capsules/minute |

Machine suitable for: | capsule Size #00 to 5 |

Power supply: | 415v 50Hz three phase (it can be changed depend on your requirement) |

Power consume: | 3.2kw |

Quantity of mould bores: | 3pcs |

Noise standard: | ﹤75dB(A) |

Weight: | 900kgs |

Overall dimension: | 660*800*1750mm |

Feature:

1. Characteristics:

It has been improved the inner design turret, and imports beeline bearings for each machine from Japan directly, so that it can be sure a longer usage-life and precision of machine.

It has been improved the inner design turret, and imports beeline bearings for each machine from Japan directly, so that it can be sure a longer usage-life and precision of machine.

The working station cam runs under the good lubricating condition, and maintains the inner lubrication of cam slot to a full extent, increasing the pressure pulverization oil pump, thus extends the operation life of the spare parts.

The working station cam runs under the good lubricating condition, and maintains the inner lubrication of cam slot to a full extent, increasing the pressure pulverization oil pump, thus extends the operation life of the spare parts.

It adopts enlarged Cam, LTPM CHINA has become the one who matches the cam of RU100 to Ru83, while it enhances the stability of the machines and extends the life of the machines to a great extent.

It adopts enlarged Cam, LTPM CHINA has become the one who matches the cam of RU100 to Ru83, while it enhances the stability of the machines and extends the life of the machines to a great extent.

It is controlled by the computer, has a stepless timing with the frequency-conversion, the numeral showing makes an easy operation and clear appearance.

It is controlled by the computer, has a stepless timing with the frequency-conversion, the numeral showing makes an easy operation and clear appearance.

Adopt Plane Spring for filling powder, this type spring can afford TWO BILLION TIMES Pressing, but never changed overall dimension. So it makes the Weight of Powder filling in an accuracy number.

Adopt Plane Spring for filling powder, this type spring can afford TWO BILLION TIMES Pressing, but never changed overall dimension. So it makes the Weight of Powder filling in an accuracy number.

Automatic Capsule Switch operated by Touch Screen avoid Dangerous Accident happens when open the switch by hand into the working station.

Automatic Capsule Switch operated by Touch Screen avoid Dangerous Accident happens when open the switch by hand into the working station.

Our quality machine use Tanshing Cam box, in automatic capsule filling machine area Honest Business is the most important, Because Customers can’t see the mechanical parts inside. So our company can promise we use the real type but never “labeling type”.

Our quality machine use Tanshing Cam box, in automatic capsule filling machine area Honest Business is the most important, Because Customers can’t see the mechanical parts inside. So our company can promise we use the real type but never “labeling type”.

The multi-bore dosing brings a precision dosage (it is controlled around ±0.75%); the good capsule applicability makes a higher capsule qualified rate (≧99%).It can be filled with the Chinese traditional medicine and the Western medicine.

The multi-bore dosing brings a precision dosage (it is controlled around ±0.75%); the good capsule applicability makes a higher capsule qualified rate (≧99%).It can be filled with the Chinese traditional medicine and the Western medicine.

Add the extra function of capsule control switch. (Control the capsule outside of the machine; it is more safely and quickly).

Add the extra function of capsule control switch. (Control the capsule outside of the machine; it is more safely and quickly).

Add the click-moving control system, makes an easier operation and clearness.

Add the click-moving control system, makes an easier operation and clearness.

Electronic Parts List:

Name | Model | Located and Brand |

Circuit Breaker | 3VU1340 3VU140 | Siemens, Germany |

Air Switch | 53X-2310/2101 | Siemens, Germany |

AC Contactor | MYZNJ-DC220V | Omron, Japan |

Switch | 6EPB31-1SH01 | Siemens, Germany |

Urgent Switch (Stop and start) | YO9 | Schneider, Germany |

Touch Screen | DOP A57BSTN | Delta |

PLC | DVP-14ES00R.2 | Delta |

Inverters | VFD-A1.5KW | Delta |

Stop Machine | CH-32-1500W | YK, Taiwan |

Vacuum Pump | 2BV2050 | TAIZHOU |

Cam | RU-83DS-6 RU-100DS-10 | Tanshing, Taiwan |

Dust Collector | XLJ Series | By own factory |

Linear Bearings | SDE12Y | SE1KO, Japan |

Linear Bearings | SDE16Y | SE1KO, Japan |

Linear Bearings | SDE20Y | SE1KO, Japan |

Linear Bearings | SDE40Y | SE1KO, Japan |

Needle Roller Bearings | NAKD30 | SE1KO, Japan |

Needle Roller Bearings | MAKD40 | SE1KO, Japan |